-

Content count

596 -

Joined

-

Last visited

-

Days Won

50

Posts posted by Casey

-

-

2 hours ago, ewaskew said:Very nice work there Casey that thing is looking real good. God Bless

Thanks! I haven't worked on it in a while but plan to get back after it soon.

-

That is awesome. I look forward to following its progress.

-

Another one to follow. That will be a neat build.

What is the purpose of the pipe in front of the rear tires in the image of #69?

-

Looking good. Can you share some detail pics of the lift axel?

-

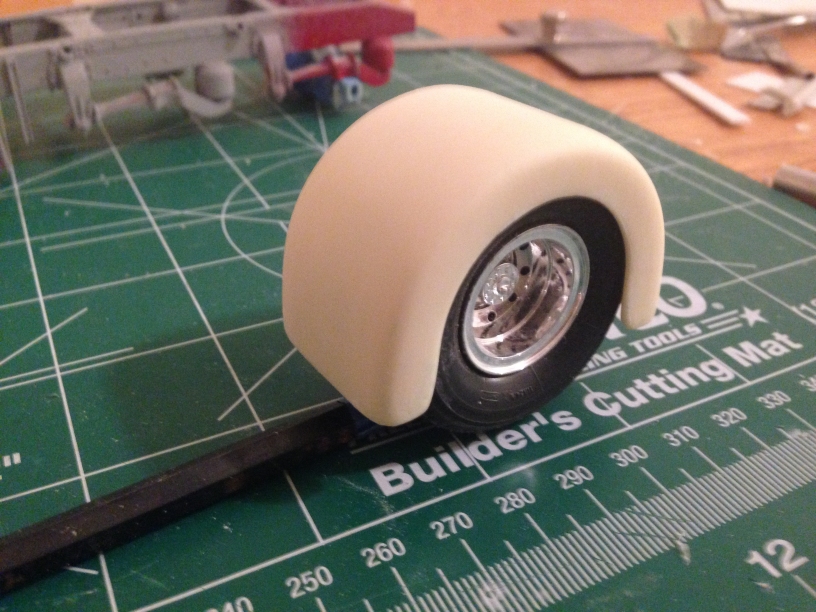

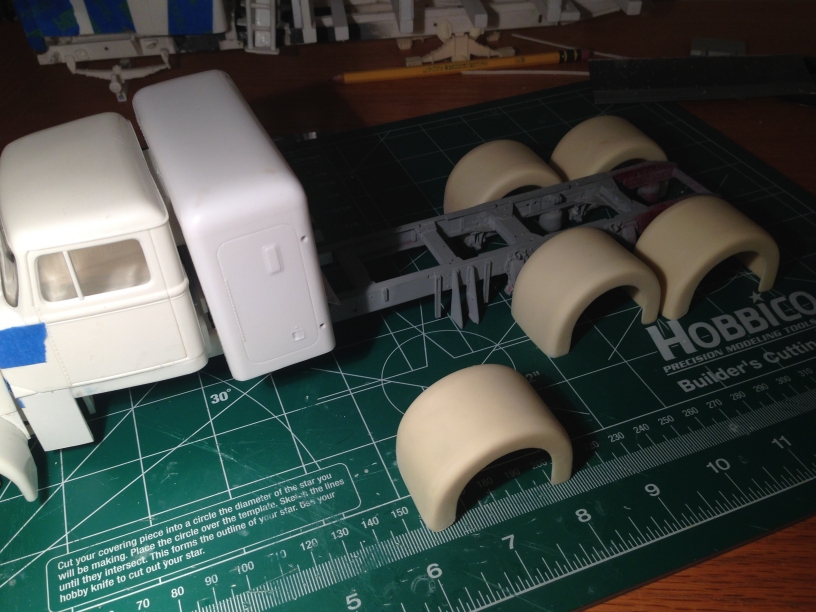

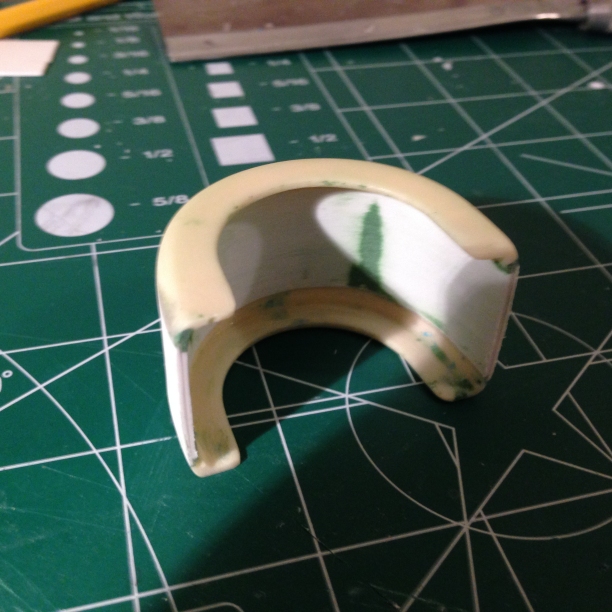

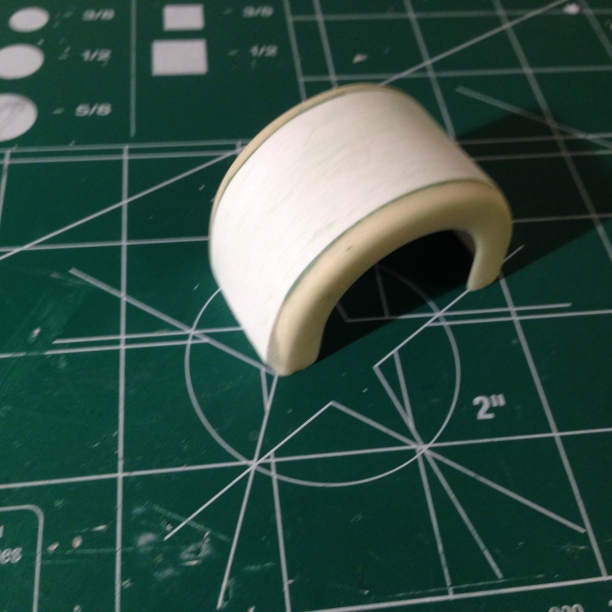

Done! They now fit snug on the ROG Peterbilt wheels and tires so I am happy. Light sanding and possibly a little (very little filler) will be need but I think that is almost impossible to avoid.

-

3 hours ago, Cornbinder said:They look way better than my resin casting experiments, I will say that.

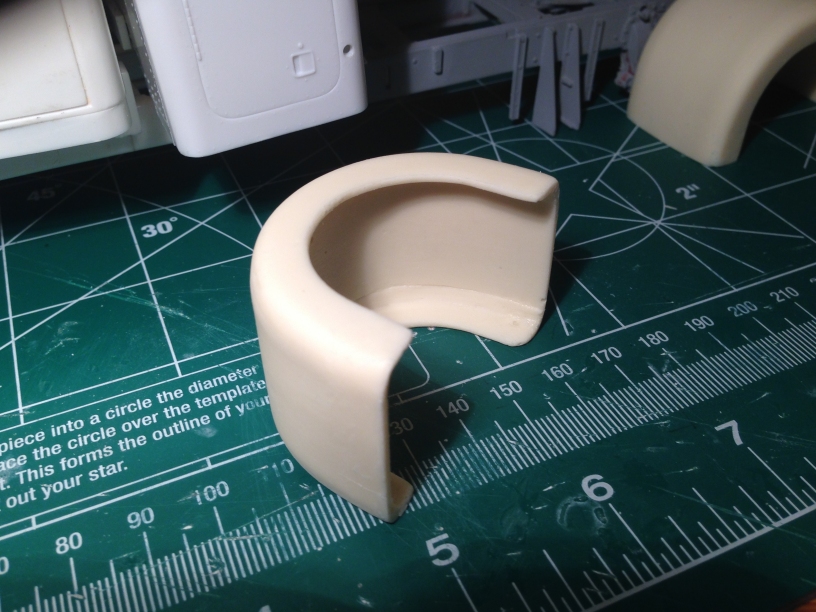

I appreciate the kind words. Unfortunately, as I began to tinker with them I discovered that they were about 1/10th of an inch to wide. I have reworked them and I have poured the first half of the mold. I hope the this attempt turns out as well as the previous one.

-

The mold was cured today and I was finally able to cast my fenders. There are very few bubbles and they have all been on the underside. They will require a little sanding and possibly a little filler. I think they turned out pretty damn good!

-

1

1

-

-

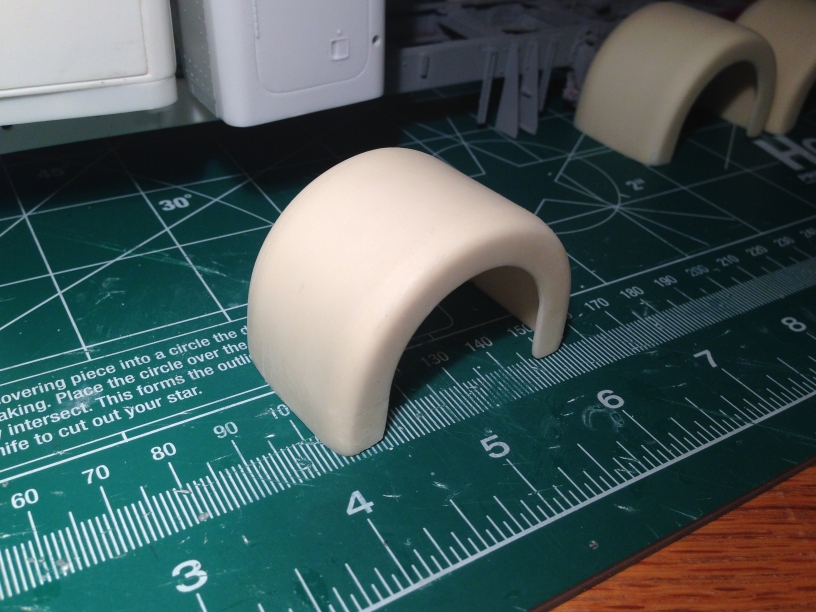

I added the center portion of the fender a couple of days ago and I have poured half of the mold for the fender. Waiting for it to cure so I can make the second half. Wish me luck!

-

2

2

-

-

As I mentioned in my previous post I decided to build a new fender to resin cast. I thought it would be easier to build one side (center), resin cast it to make the other side and then add the center. This was my first attempt at resin casting but after several failed attempts (left) at both making the mold and casting the part, I think I finally have results that I can work with (right). I just had a couple of small air bubbles that can be easily filled.

-

On 10/3/2015 at 11:46 PM, Cornbinder said:I've pondered making a few fenders like that. Did you roll a flat piece of plastic for the top, or use something that was already rounded, like a cut-down pill bottle?

I thought I had replied to this but looks like I didn't. On the one above I just used flat sheet styrene and beveled the corner. However, I wanted to round the corners more and thus decided to build a new one to resin cast.

-

1

1

-

-

Facebook registration and login is now enabled! Please let me know if you experience any issues.

-

-

Any updates on this one?

-

At $177 plus a donor, plus extras...I can see why.

-

Impressive looking conversion. I look forward to seeing what you do with it.

--Casey

-

-

Nice build. I took a ride in one of these years ago. Astros are definitely "truck, basic, 1 each" (military humor).

-

Looking real nice! Pretty flashy for an old Transtar!

-

I look forward to following the progress on this one! Please keep us updated.

-

1

1

-

-

Casey, if I'm not mistaken, I got those two-holers from KFS. They came with hubs too.

Thanks. I'll have to get me some of those.

-

1

1

-

-

Thanks for the tip and link!

-

-

I look forward to updates on this one....

-

Those are some nice looking wheels. Where are they from?

My fleet

in Model Truck Workbench

Posted

Looking good. I love that color.