-

Content count

165 -

Joined

-

Last visited

-

Days Won

29

Posts posted by Gary Chase

-

-

-

-

Fantastic build

-

Very cool build

-

1

1

-

-

Wow, man you got some serious skills, well done

-

1

1

-

-

Very cool build

-

Outstanding build, did you do a build thread on this?

-

22 hours ago, vincen47 said:Daycab or kit sleeper?

Going day cab with headache rack to go with my fleet,,,,,,,when I get back to it. With warmer weather we are getting our garden planted under hot hoop houses and I am heading down south to see my kids/grandkids😜😉😁

-

2

2

-

-

Wow, nicely done, love the front suspension and details

-

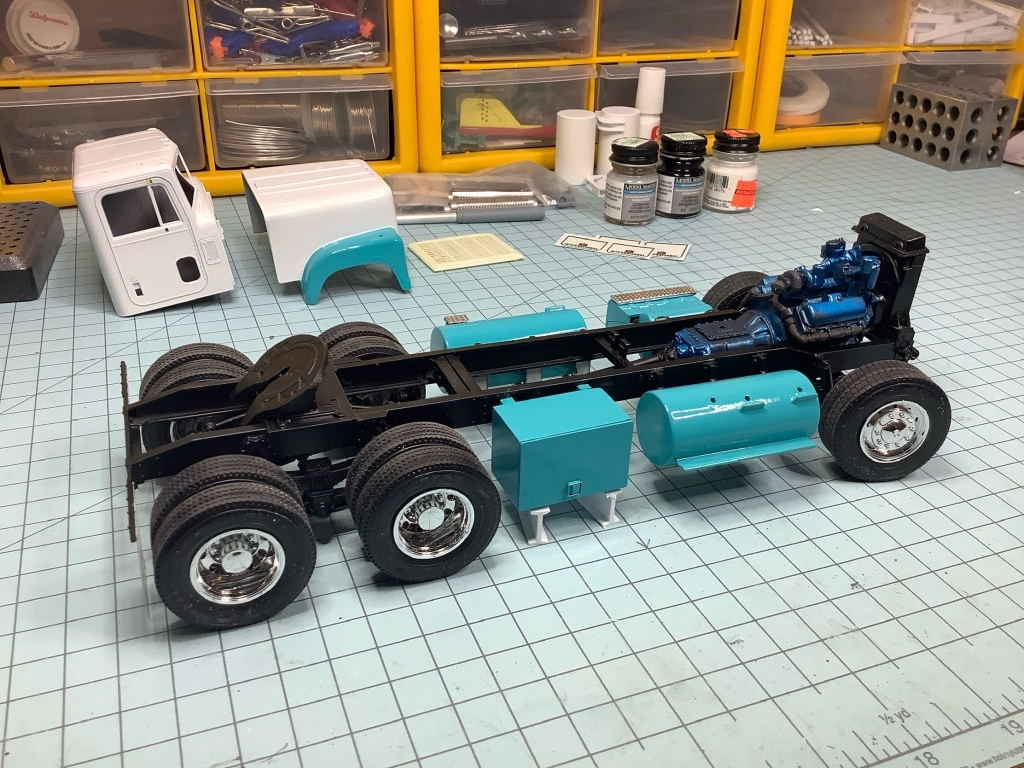

7 hours ago, Johnny M said:That's gonna be nice. The painted tanks will definitely be an upgrade. Engine and trans look great.

But what kind of engine is that? Looks like it has a turbo propelled by both banks of cylinders -- is it like an 8V-92 or something? (Duh --not the world's biggest Detroit expert)

Johnny

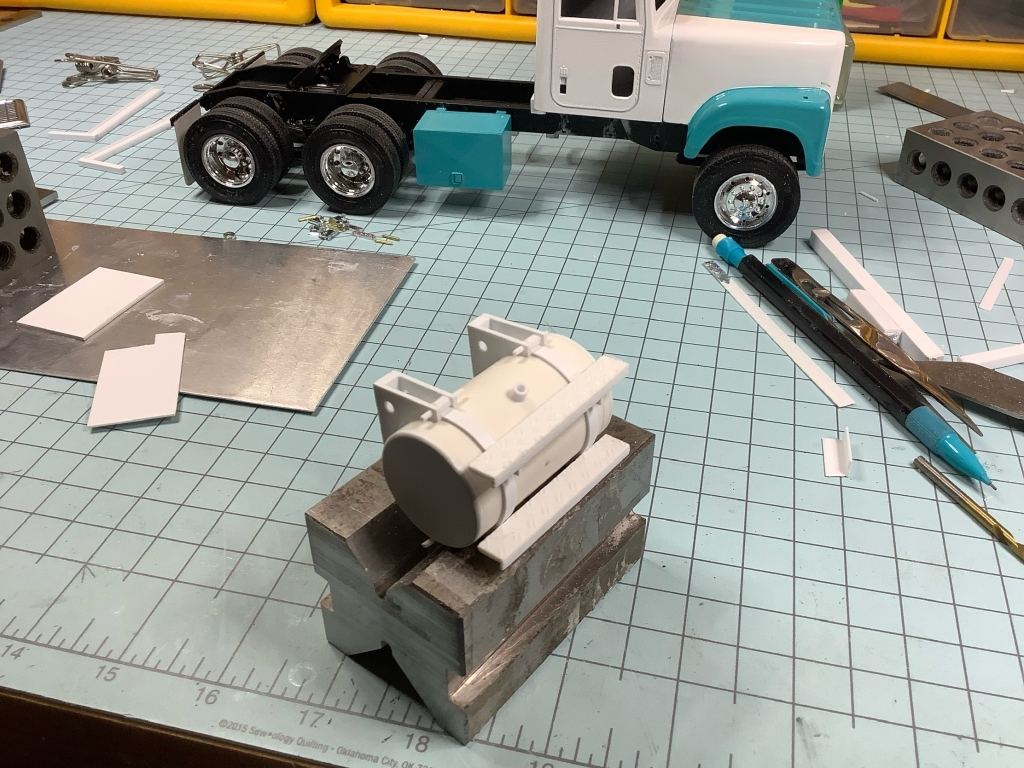

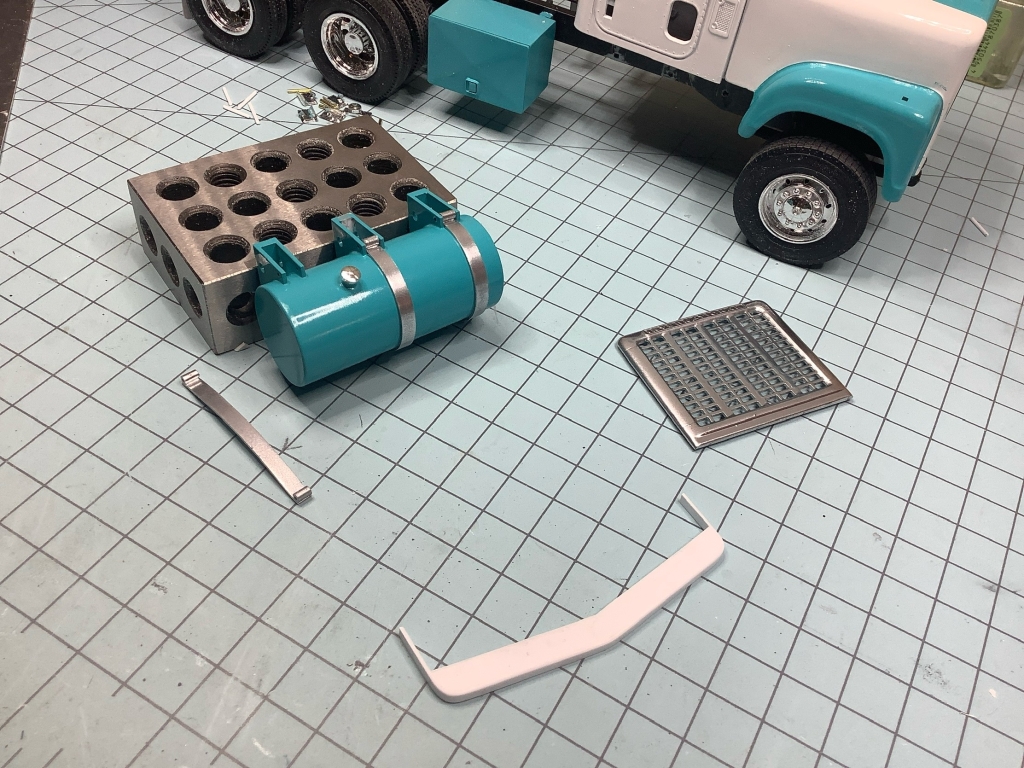

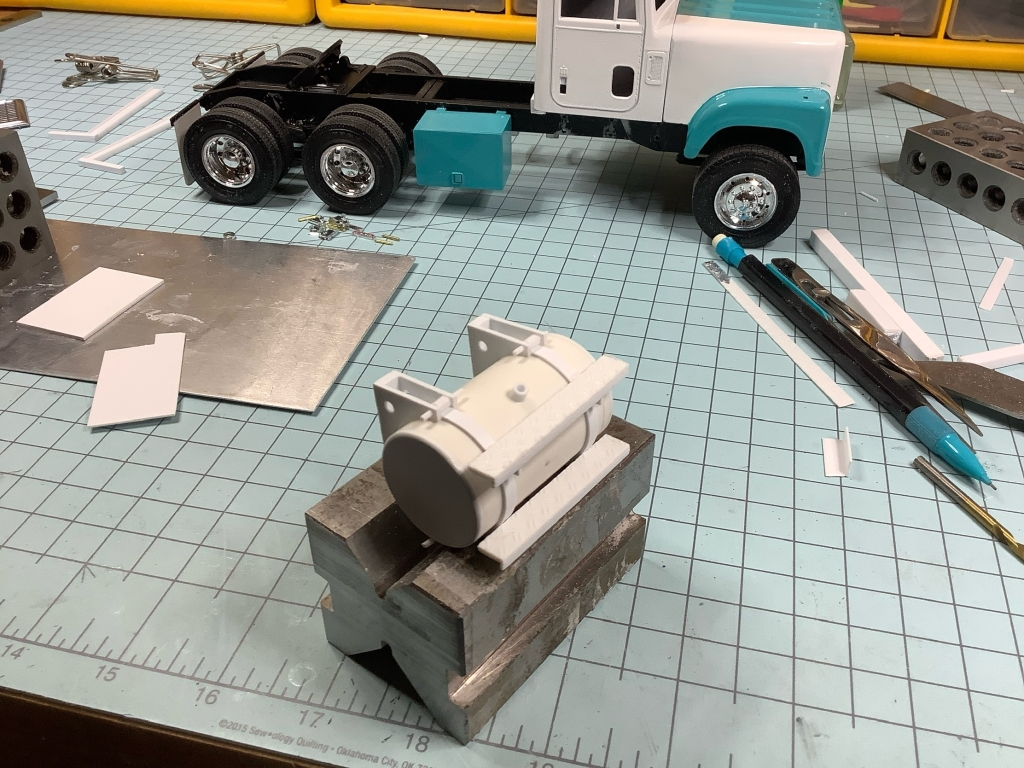

It’s the engine that came in the kit with a single turbo, pretty standard fare in the Ertl/AMT International kits. A lot of the parts don’t fit well, got to adjust a lot

-

2

2

-

-

-

-

50 minutes ago, vincen47 said:I haven’t ordered anything from them yet, so I’m looking forward to your opinion.

Will do, I will go over it before I do anything to it.

-

1

1

-

-

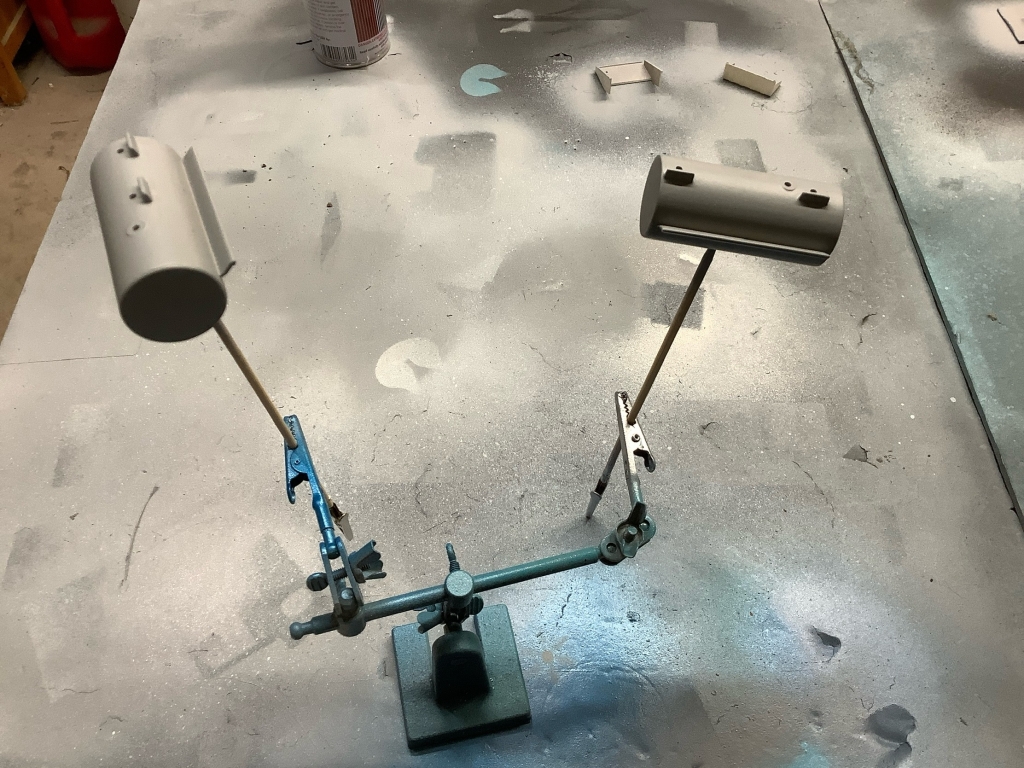

-

9 minutes ago, Chris K said:Those look pretty nice.

They do in pictures, I will post up how the fit, quality and adjustments when I get them.

-

-

-

Nice work, looking good

-

Wow that looks good

-

13 hours ago, Eric said:Brian

On your air tanks they would have been set up with two air tanks the first one would be a tank with a centre separator effectively making it two tanks in one.

In this center divider wall there would be a check valve the air from the compressor would be pumped into this first tank was known as the wet tank where the moisture in the air would collect as that compressed air cooled.

Each tank would have a mechanical drain cock to dump any water collected . The wet tank would not have any air lines running away from it as it was only used as a wet tank the other half of that tank was referred to as the primary tank this tank would be used to operate half of the brake system we'll say the front brakes so there would be an air line running up front to the treadle valve.

From the primary tank there would also be an air line which ran from the primary tank to the secondary tank this air line would have a spring loaded check valve known as a priority valve it would allow the primary tank to pressurize to 70 psi before it would allow any air into the secondary tank this was done to separate the two brake systems front and rear so if an air line where to blow or be severed the other tank would still have air to operate it's related brake system.

The secondary tank was used to operate the rear brakes and as such had an air line running to the treadle valve as well.

From the treadle valve there would be at least two air lines one running to the front brakes and one running to the rear brakes .

The front brake supply would have a QR ( quick release ) valve in line to aid in dumping air on brake release to speed up the brake release.

The rear brakes may have been the same way or which was more likely the case would have had a relay valve close to the rear axle/s this valve was sometimes mounted right on the secondary air tank next to the axle , the object here was to feed enough air supply to the rear brakes to run as many brakes as there are axles brakes at a faster rate.

This secondary air supply to the treadle valve would also be used to supply air to the yellow parking brake valve on the dash this valve was pushed in to release the parking/ spring operated brakes and was setup so that in the event of air pressure lose the ( below 60 psi the valve would pop out and dump the air off the parking /spring brake chambers which would allow the springs brake chambers to apply the rear brakes.making the system fool proof.

This valve as mentioned would be either feed from the secondary tank directly ( screwed into the air tank or by a larger air line this relay valve would also have an air line which is run from the treadle valve as a signal line to operate the relay valve the relay valve would also have a QR valve built into it to speed brake release for the rear brakes as well.

The only other line connected to the secondary tank would be for accessories like air suspension,air wiper motors,air horns etc this air supply would be connected to another priority valve screwed into the air tank which would maintain 60 psi in the secondary tank in the event of a major air leak in any of the accessories.

If the vehicle had air suspension it would likely have another air tank feed by this supply.

There would also be a smaller air line from each tank one primary and one secondary these would run directly to the dash to operated either a dual all in one air gauge or two air gauges on the dash.

Hope this helps

Eric

That is some great info and explanation, going to print this out. Question: I have seen an air tank for each rear axle, 2axles, 2tanks, 4 axles, 4 tanks. As I understand these where for air brakes and air suspension?

-

3 hours ago, Eric said:Gee Gary thars a lot of super singles!

Yup, I just got enough, the newer logging trucks run singles all around, a couple years ago, just the lift axles where wide singles, prior to that they ran duals on all axles except steering.

-

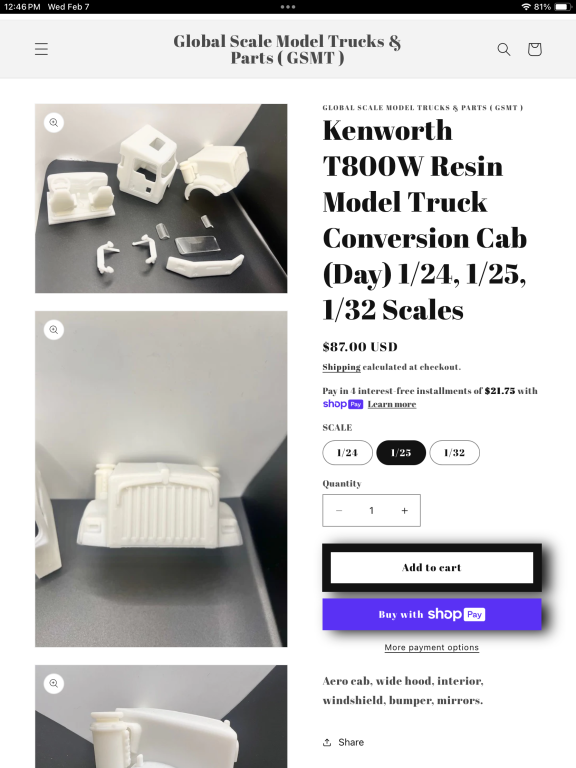

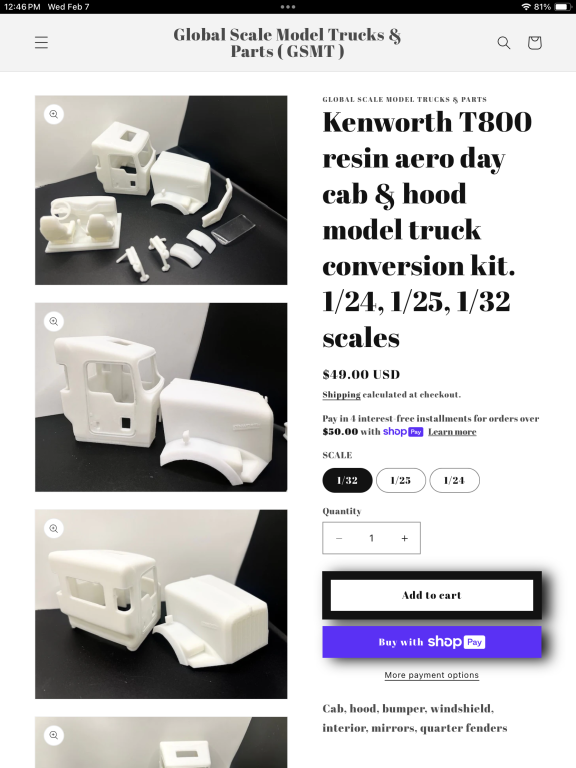

Doing a little research last night on the T800. I didn’t realize that Kenworth still offers the T800 in a flat windshield (like the W900) and a curved windshield (like the T600, one piece glass and two piece glass). It was offer in a long hood, short hood and wide hood. Also noticed that you could get it with the newer doors (no vent window and step down window) as well as the standard door with vent window. By picking up a T800 hood from ST Supply you could build several versions of new Kenworth trucks, being that non of the molded makers are producing much of the newer trucks.

Doing a little research last night on the T800. I didn’t realize that Kenworth still offers the T800 in a flat windshield (like the W900) and a curved windshield (like the T600, one piece glass and two piece glass). It was offer in a long hood, short hood and wide hood. Also noticed that you could get it with the newer doors (no vent window and step down window) as well as the standard door with vent window. By picking up a T800 hood from ST Supply you could build several versions of new Kenworth trucks, being that non of the molded makers are producing much of the newer trucks.

-

1

1

-

-

Just picked up this kit, will be watching what you do with your build.

-

10 hours ago, vincen47 said:This will be a neat build. You’ve got a great start. Does the second axle have a passive or active steering system? Also, how many of the drive axles are powered? I’ve seen those trucks during trips to northern Michigan, but I’ve never checked them out up close.

The newer loggers have a second steering axle, older ones had a non-steering lift axle. Most of these trucks are twin screw, very rare to see a tri-drive up here. They have an air lift in front and behind the drive axles. When I talk to the guys, the conversation is always about a lighter truck to carry more pay load and who is getting the most decked out new truck.

-

1

1

-

International 5300

in Model Truck Workbench

Posted

Thanks, we will see how it turns out. My builds are very fluid and subject to changes as I build as I am on my third set of fuel tanks on this one.