-

Content count

596 -

Joined

-

Last visited

-

Days Won

50

Posts posted by Casey

-

-

Those are some nice builds. Hopefully you invited him to the site.

-

@Cornbinder

What happened to the images in the first post?

-

I did a few test fits and it looks like I'll be rebuilding them. Just a bit too narrow...

-

1

1

-

-

I dig it. The headache rack is very nice.

-

1

1

-

-

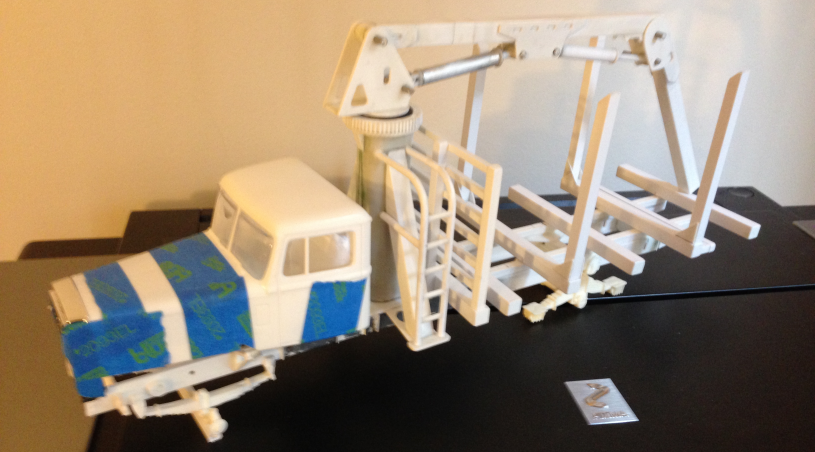

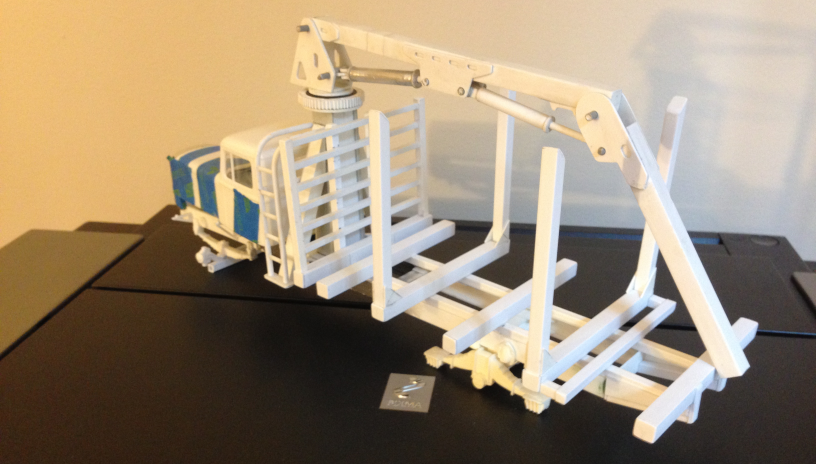

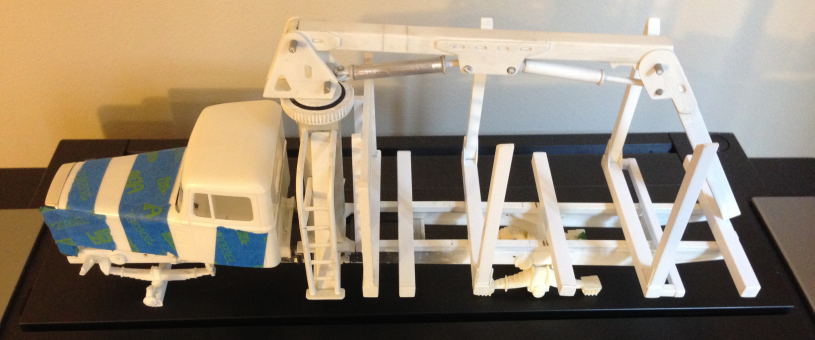

I have made some progress on the build over the last week or so.

- Rebuilt the loader's ladder.

- Made a lot of progress on rebuilding the log bed. It was not "heavy" enough.

- Swapped the 65K rear suspension for a 55K set-up.

It's funny how some parts look much larger/thicker in the images than they are. Photography is obviously not my thing...

-

2

2

-

I'm going to need some for a planned project so I thought I would give building one a shot. The inside of the fender is 1.1" wide (27.5") they are a tight fit on the ROG Peterbilt and AMT Autocar wheels/tires but I think they will be okay.

Any thoughts on the inside width and/or the overall look?

--Casey

-

Thank you. I'll keep plugging away at it and hopefully it will turn out pretty decent.

-

Incredible talent. I look forward to watching it progress.

-

I had to backtrack some of the build. I have reworked the drive gear main boom and upper boom support, and added the outer boom, cylinders and a few other odds and ends. Progress has been slow as I am learning as I build and it needs a little putty and sanding but I am pretty happy thus far.

Note: not sure if the part names are correct, not an expert...

-

2

2

-

-

Filling it with sand is a technique used in the tube bending industry but it can be hard to do on our scale models.

I find a piece of round plastic rod that fits snug inside the tube, it doesn't have to be very tight, but the tighter the better. Let the insert exceed the tubing and you should be able to pull it out after the bend is done. You may need some good pliers to pull the plastic rod out of the aluminium tube, that's why you don't want your insert to be overly tight.

Beerz, Felix

I will be giving that a try! Thanks!

-

A great example of the flexibility of model truck building. Definitely not "box stock".

-

Very cool. Great concept and color choices. Are the tail lights from the kit?

-

Beautiful build! I would love to have that kit.

-

The weathering is spot on.

-

The paint looks amazing...

-

Very cool. I have that kit stashed away. I think I will make it a day cab heavy hauler.

-

Nice combo.

-

Checked out your sites, some very cool stuff. I would love to know the story behind the yellow wrecker from your Flickr page.

-

Are kits of American trucks readily available in Europe or do you order them fro the US?

-

It looks like it should be on the model box. Very nice!

-

Yet another nice build.

-

1

1

-

-

Very nice

-

1

1

-

-

I definitely prefer the black frame for that truck. Nice Job.

-

1

1

-

-

Very nice. The headache rack looks real good.

-

1

1

-

GW Trucks

in Model Truck Kit Discussion

Posted

Nice stuff. Does he have a website?